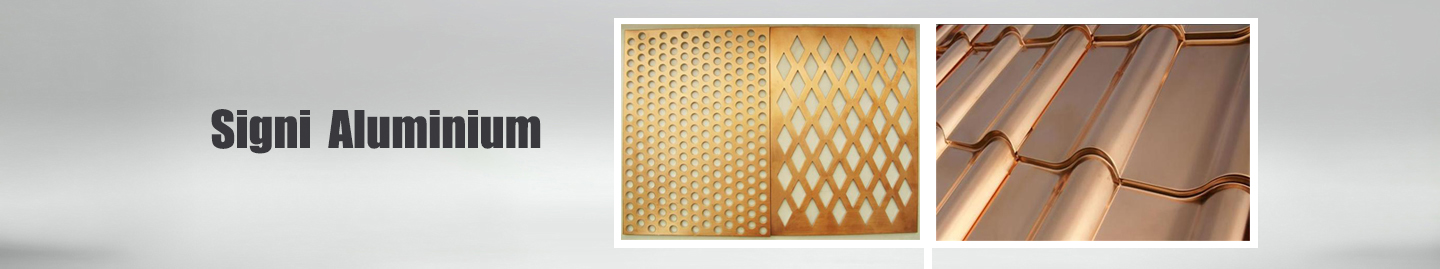

APPLICATION

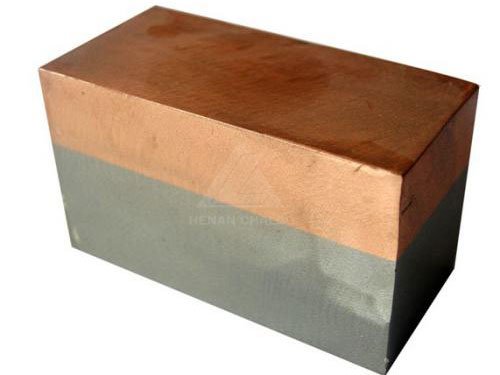

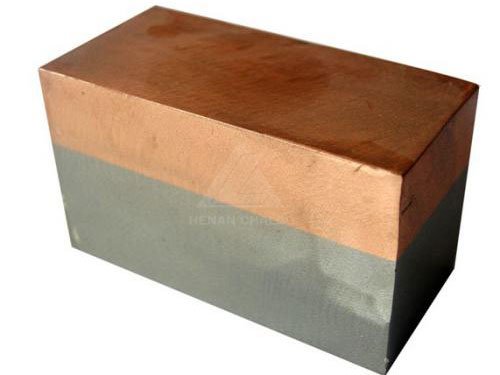

Copper steel explosive bonded clad sheet plate

Editor :frank

Time :2019-09-24 17:58:00

The general composite plate manufacturing methods include: filled metal steel rolling method, explosive composite method, rolling and crimping method, surfacing welding method, etc., considering the characteristics of Copper, the industry often uses explosive composite method or pressure bonding method, and The actual production method includes the explosive composite method, and the rolling and crimping method includes the 2 thick plate rolling method 3 continuous hot rolling method. The explosive composite method is usually carried out at room temperature, and the plate is assembled by rolling and crimping, and heated and rolled. The main points of the copper steel explosion bonded clad sheet plate are to place a certain amount of explosives on the top of the two sheets to be crimped. From the end of the explosive, the explosion speed is several kilometers per second. By virtue of the explosive energy, the Copper plate collides with the substrate steel plate at the impact point. The steel plate and the plate exhibit fluid behavior under a very high deformation speed and ultra high pressure. The oxide film and the gas adsorption layer on both surfaces are used as a metal jet to eliminate the joint between the clean surface and the surface, which is called cold joint.

The Copper composite plate manufactured by the method can continue to heat up to a plate thickness of 4 mm, so it is also called explosive composite method, and the copper steel explosive cladding sheet plate’s thick plate rolling method uses Copper plate (composite material) and steel plate. (substrate) into the plate, in this case, between the Copper plate and the steel into the appropriate intermediate embedded material, and then under high vacuum by electron beam welding into the heating furnace, after strong pressure on the thick rail machine To the required thickness, so that the Copper plate and the steel plate are actually connected, and the outer portion is cut and separated into two plates.

The Copper composite plate manufactured by the method can continue to heat up to a plate thickness of 4 mm, so it is also called explosive composite method, and the copper steel explosive cladding sheet plate’s thick plate rolling method uses Copper plate (composite material) and steel plate. (substrate) into the plate, in this case, between the Copper plate and the steel into the appropriate intermediate embedded material, and then under high vacuum by electron beam welding into the heating furnace, after strong pressure on the thick rail machine To the required thickness, so that the Copper plate and the steel plate are actually connected, and the outer portion is cut and separated into two plates.

Related :

- Copper-Aluminium Bimetal Clad Sheet2023-04-27

- Bimetallic copper aluminum washers2020-06-30

- copper-aluminium bimetal clad sheet2020-07-08

- copper coated aluminium busbar2021-03-01

- aluminum copper clad laminate sheet2021-03-15

- is copper clad aluminum wire good?2021-03-30