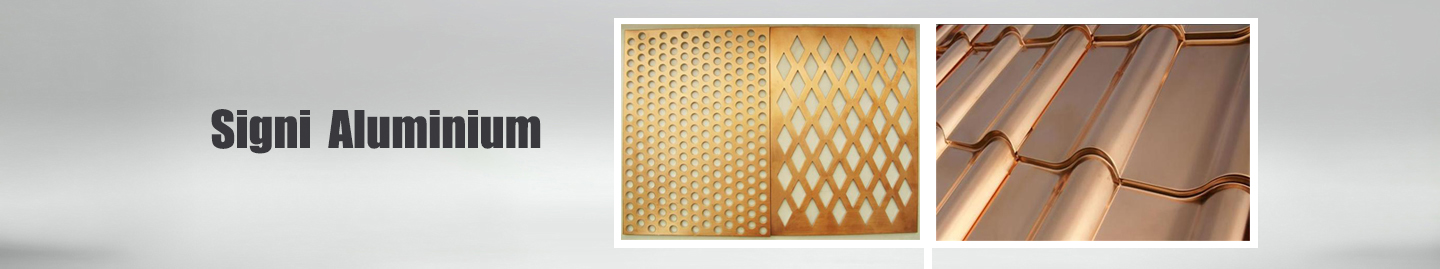

APPLICATION

aluminum copper clad laminate sheet

Editor :frank

Time :2021-03-15 17:35:00

Copper has good electrical conductivity, thermal conductivity, and ductility. It has a wide range of applications, but it is a scarce resource, so the cost is high, and the application of conversion is limited; aluminum materials are rich in resources, which are conductive and insulating. Although it is weaker than copper in other properties, it has low density, light weight and low cost; if copper and aluminum materials can be combined, it will become one.

After cleaning the composite surface of two copper plates and one aluminum plate, they are stacked and placed. After heating by heater, they are calendered and bonded. The thickness of the formed composite plate can reach less than 1 mm. The joint surface of aluminum copper clad laminate sheet is closely combined, and the two are well integrated. In addition to the advantages of both copper and aluminum sheet, its processing performance is also improved. When in use, the surface of the composite plate is copper plate, which can be used in the occasion of conducting electricity and heat, instead of pure copper plate.

The aluminum copper clad laminate sheet comprises an aluminum plate and two layers of copper plates which are respectively tightly pressed on both sides of the aluminum plate. The utility model not only has the characteristics of good conductivity, thermal conductivity and ductility of copper plate, but also has the advantages of light weight and low cost of aluminum plate, and has high cost performance ratio.

Signi aluminum independently developed a variety of high-performance high aluminum copper clad luminate sheet. The processing technology adopts thermoelectric separation structure to better solve the heat dissipation problem of some high-power LED lamp beads, especially to provide better heat dissipation effect for high-power 100 w-1000 w LED lighting products. The products are widely used in LED lighting, high-power power supply, automobile, electric power, electronics, medical equipment, mechanical equipment and other fields.

After cleaning the composite surface of two copper plates and one aluminum plate, they are stacked and placed. After heating by heater, they are calendered and bonded. The thickness of the formed composite plate can reach less than 1 mm. The joint surface of aluminum copper clad laminate sheet is closely combined, and the two are well integrated. In addition to the advantages of both copper and aluminum sheet, its processing performance is also improved. When in use, the surface of the composite plate is copper plate, which can be used in the occasion of conducting electricity and heat, instead of pure copper plate.

The aluminum copper clad laminate sheet comprises an aluminum plate and two layers of copper plates which are respectively tightly pressed on both sides of the aluminum plate. The utility model not only has the characteristics of good conductivity, thermal conductivity and ductility of copper plate, but also has the advantages of light weight and low cost of aluminum plate, and has high cost performance ratio.

Signi aluminum independently developed a variety of high-performance high aluminum copper clad luminate sheet. The processing technology adopts thermoelectric separation structure to better solve the heat dissipation problem of some high-power LED lamp beads, especially to provide better heat dissipation effect for high-power 100 w-1000 w LED lighting products. The products are widely used in LED lighting, high-power power supply, automobile, electric power, electronics, medical equipment, mechanical equipment and other fields.

Related :

- Copper-Aluminium Bimetal Clad Sheet2023-04-27

- Bimetallic copper aluminum washers2020-06-30

- copper-aluminium bimetal clad sheet2020-07-08

- copper coated aluminium busbar2021-03-01

- aluminum copper clad laminate sheet2021-03-15

- is copper clad aluminum wire good?2021-03-30