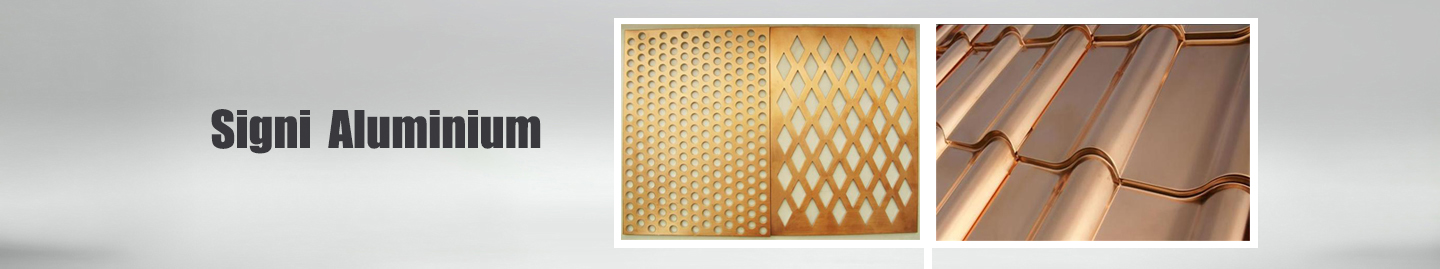

APPLICATION

Copper-aluminum composite metallic materials

Editor :frank

Time :2019-11-26 17:19:00

Copper-aluminum composite metallic materials is a new material that uses various composite technologies to achieve metallurgical bonding at the copper interface and the aluminum interface. Copper-aluminum composite metallic materials have the advantages of copper: good electrical conductivity, good thermal conductivity, easy soldering, low contact resistance, easy plating, and beautiful appearance. At the same time, it also has the characteristics of aluminum's low cost, light weight, good heat dissipation, and economy. In this paper, the preparation and interface characteristics of its composite method have been studied to a certain extent.

At present, with the rapid development and progress of the social economy, new technologies and new industries continue to appear, making people's performance requirements for materials used in various practical projects increasingly higher. However, due to the limited reserves of a single metal material in nature, for a single metal material, its comprehensive performance is insufficient, which makes it extremely limited in application fields, and Copper-aluminum composite metallic materials have emerged at the historic moment.

2 Characteristics of Copper-aluminum composite metallic materials

Copper metal reserves are not much in nature, and the price is relatively high, which has prompted people to find alternative materials in the electrical industry. Aluminum has abundant natural reserves, low price, low density, and good electrical conductivity. It is a conductive material with excellent electrical conductivity. Therefore, as early as the 1960s, the idea of "substituting aluminum with copper" has been proposed. However, when using aluminum wire as a conductor for transmitting electrical energy, metal aluminum has low strength, is susceptible to deformation and corrosion, and is liable to form a strong oxide film on the surface, which results in a large contact resistance. Difficult to become a good conductive material used in the electrical industry. And the difficulty of connection of aluminum metal also limits its further promotion.

The emergence of Copper-aluminum composite metallic materials has improved these shortcomings, making them widely used in communication, electronics, electrical appliances, automobiles, and household appliances. Among many important parts in power transmission and electrical and electronic equipment, in order to reduce weight and save costs, copper-aluminum layered composite metallic materials are often used for manufacturing. Similarly, copper-clad aluminum wires are also a very typical application of bimetal composites in the power electronics industry. From the above, it can be seen that the copper-aluminum composite metallic material overcomes the problems of large contact resistance and easy creep of pure aluminum wires, and can greatly reduce the amount of expensive copper compared to all-copper wires.

Copper-aluminum composite methods can be divided into solid-solid phase composite method, solid-liquid phase composite method, and liquid-liquid phase composite method. The bonding strength between copper and aluminum and the transition layer of composite samples prepared by different composite methods and process parameters There are differences in thickness and so on. But in the end, each composite method is to make copper react at the interface and complete good diffusion, and finally achieve metallurgical bonding to obtain copper-aluminum composite metallic materials with good performance.

At present, with the rapid development and progress of the social economy, new technologies and new industries continue to appear, making people's performance requirements for materials used in various practical projects increasingly higher. However, due to the limited reserves of a single metal material in nature, for a single metal material, its comprehensive performance is insufficient, which makes it extremely limited in application fields, and Copper-aluminum composite metallic materials have emerged at the historic moment.

2 Characteristics of Copper-aluminum composite metallic materials

Copper metal reserves are not much in nature, and the price is relatively high, which has prompted people to find alternative materials in the electrical industry. Aluminum has abundant natural reserves, low price, low density, and good electrical conductivity. It is a conductive material with excellent electrical conductivity. Therefore, as early as the 1960s, the idea of "substituting aluminum with copper" has been proposed. However, when using aluminum wire as a conductor for transmitting electrical energy, metal aluminum has low strength, is susceptible to deformation and corrosion, and is liable to form a strong oxide film on the surface, which results in a large contact resistance. Difficult to become a good conductive material used in the electrical industry. And the difficulty of connection of aluminum metal also limits its further promotion.

The emergence of Copper-aluminum composite metallic materials has improved these shortcomings, making them widely used in communication, electronics, electrical appliances, automobiles, and household appliances. Among many important parts in power transmission and electrical and electronic equipment, in order to reduce weight and save costs, copper-aluminum layered composite metallic materials are often used for manufacturing. Similarly, copper-clad aluminum wires are also a very typical application of bimetal composites in the power electronics industry. From the above, it can be seen that the copper-aluminum composite metallic material overcomes the problems of large contact resistance and easy creep of pure aluminum wires, and can greatly reduce the amount of expensive copper compared to all-copper wires.

Copper-aluminum composite methods can be divided into solid-solid phase composite method, solid-liquid phase composite method, and liquid-liquid phase composite method. The bonding strength between copper and aluminum and the transition layer of composite samples prepared by different composite methods and process parameters There are differences in thickness and so on. But in the end, each composite method is to make copper react at the interface and complete good diffusion, and finally achieve metallurgical bonding to obtain copper-aluminum composite metallic materials with good performance.

Related :

- Copper-Aluminium Bimetal Clad Sheet2023-04-27

- Bimetallic copper aluminum washers2020-06-30

- copper-aluminium bimetal clad sheet2020-07-08

- copper coated aluminium busbar2021-03-01

- aluminum copper clad laminate sheet2021-03-15

- is copper clad aluminum wire good?2021-03-30