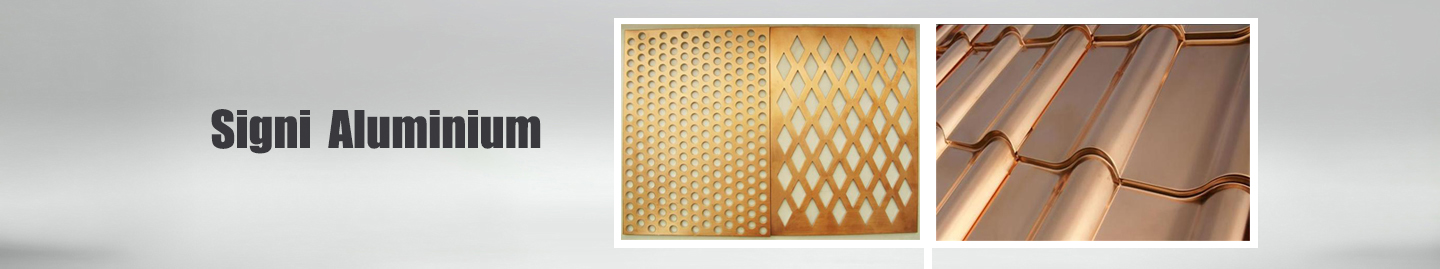

APPLICATION

Aluminum laminated stainless steel plate

Editor :frank

Time :2020-05-12 17:49:00

One of the most well-known applications of multi-layer application materials is domestic and commercial cooking utensils. Combining the corrosion resistance, plasticity and compatibility with food and the aluminum or copper core layer of the stainless layer on the front and back sides, the applied material has become the best material for cooking equipment.

Through the continuous heat application technology added to the traditional cold application technology, stainless steel / aluminum / stainless steel laminated plate have been added to the Signi cookware series since 2012. Signi can laminate countless layers of materials, such as 3 or 5 layers of aluminum alloy material or single layer copper core material with austenitic stainless steel (304) and induction-ready ferritic stainless steel (430)

Signi can easily change the thickness ratio of each layer of material. It can apply a variety of different metal materials to press out a unique new material or one of the many traditionally applied metal materials seen on the market today. Two-layer application metal materials such as stainless steel / aluminum are also commonly used in special applications such as iron soleplates and the like. In the stainless steel / aluminum / stainless steel laminated plate, the thickness is available in the range of 0.070 inches-0.160 inches, and the width is up to 24 inches. Signi can provide strips, plates or punched pieces, and the materials are deep drawn and tempered to prepare for molding. Two layers of stainless steel / aluminum application materials can produce thickness ranging from 0.013 inches to 0.200 inches, and stainless steel is No. 8 mirror.

Through the continuous heat application technology added to the traditional cold application technology, stainless steel / aluminum / stainless steel laminated plate have been added to the Signi cookware series since 2012. Signi can laminate countless layers of materials, such as 3 or 5 layers of aluminum alloy material or single layer copper core material with austenitic stainless steel (304) and induction-ready ferritic stainless steel (430)

Signi can easily change the thickness ratio of each layer of material. It can apply a variety of different metal materials to press out a unique new material or one of the many traditionally applied metal materials seen on the market today. Two-layer application metal materials such as stainless steel / aluminum are also commonly used in special applications such as iron soleplates and the like. In the stainless steel / aluminum / stainless steel laminated plate, the thickness is available in the range of 0.070 inches-0.160 inches, and the width is up to 24 inches. Signi can provide strips, plates or punched pieces, and the materials are deep drawn and tempered to prepare for molding. Two layers of stainless steel / aluminum application materials can produce thickness ranging from 0.013 inches to 0.200 inches, and stainless steel is No. 8 mirror.

Related :

- Copper-Aluminium Bimetal Clad Sheet2023-04-27

- Bimetallic copper aluminum washers2020-06-30

- copper-aluminium bimetal clad sheet2020-07-08

- copper coated aluminium busbar2021-03-01

- aluminum copper clad laminate sheet2021-03-15

- is copper clad aluminum wire good?2021-03-30