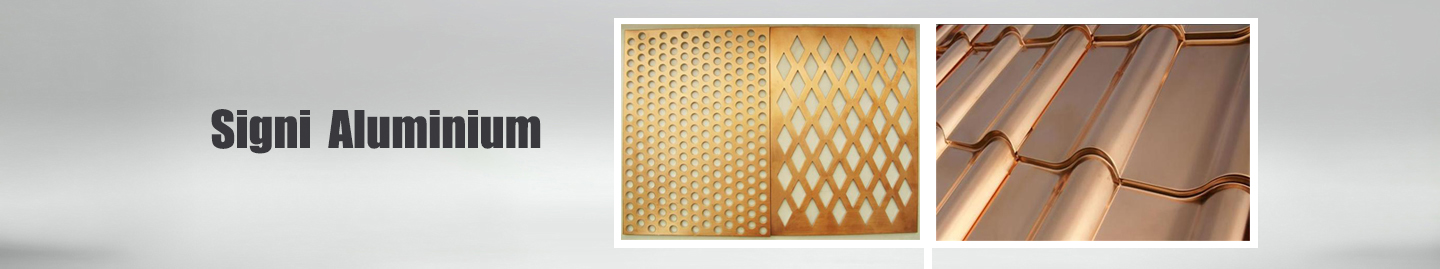

APPLICATION

Al Cu clad plate

Editor :frank

Time :2020-01-07 17:50:00

Copper and aluminum are one of the most common metal materials and each has different properties. The heat resistance of copper is better, it will melt at a temperature of about 1000 degrees, but the strength of this material is relatively poor, especially the pure copper is very soft. The high-performance aluminum alloy is comparable to the strength of steel, but its heat resistance is poor. Generally, a temperature of 500 ° C is sufficient to melt it away. And if these two materials are combined, they can have their own advantages at the same time, which is a very common Al Cu clad plate on the market today.

And if you want to make a perfect Al Cu clad plate, you also need to apply a special process, otherwise the connection between the two will not be strong. Generally, there are many ways to produce this kind of plate, but they are different The performance of the products produced by the process will also be slightly different. The most common and simple method is through cold rolling. It does not need to heat two metals. At ordinary temperatures, high pressure is applied through the rollers of the machine, so that a copper plate and an aluminum plate can be well combined. Together, but we can also imagine that the effect of this combination is relatively poor, so it can only be used in general occasions.

And if the hot-rolled process is used to produce Al Cu clad plate, the two metals can be better fused together under high temperatures, and there will be no obvious gaps in the middle, so its performance will be better, at some temperatures You can also have it on higher occasions. The above are two more traditional production methods, and now there are more advanced processes. For example, the plate produced by the explosive composite method is also better in performance, but the price is relatively more expensive.

And if you want to make a perfect Al Cu clad plate, you also need to apply a special process, otherwise the connection between the two will not be strong. Generally, there are many ways to produce this kind of plate, but they are different The performance of the products produced by the process will also be slightly different. The most common and simple method is through cold rolling. It does not need to heat two metals. At ordinary temperatures, high pressure is applied through the rollers of the machine, so that a copper plate and an aluminum plate can be well combined. Together, but we can also imagine that the effect of this combination is relatively poor, so it can only be used in general occasions.

And if the hot-rolled process is used to produce Al Cu clad plate, the two metals can be better fused together under high temperatures, and there will be no obvious gaps in the middle, so its performance will be better, at some temperatures You can also have it on higher occasions. The above are two more traditional production methods, and now there are more advanced processes. For example, the plate produced by the explosive composite method is also better in performance, but the price is relatively more expensive.

Related :

- Copper-Aluminium Bimetal Clad Sheet2023-04-27

- Bimetallic copper aluminum washers2020-06-30

- copper-aluminium bimetal clad sheet2020-07-08

- copper coated aluminium busbar2021-03-01

- aluminum copper clad laminate sheet2021-03-15

- is copper clad aluminum wire good?2021-03-30