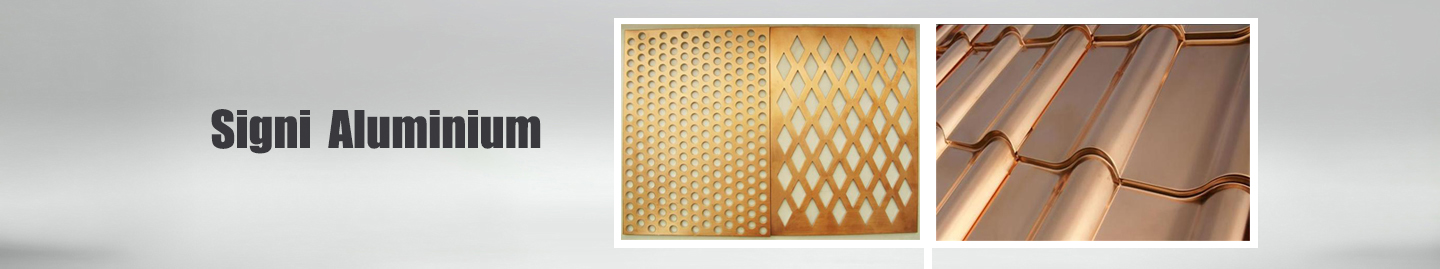

Copper Aluminium Transition Plate

1. What is Bimetal Transition Plate

Bimetal Transition Plate refers to a composite material formed by metallurgical combination of two or more different metals. Common titanium-steel composites, copper-steel composites, titanium-zinc composites, titanium-nickel composites, nickel-steel composites, copper-aluminum composites, Nickel-copper composite, etc.

Transition plate production process

2. Bimetal Transition Plate methods are as follows, let's understand together.

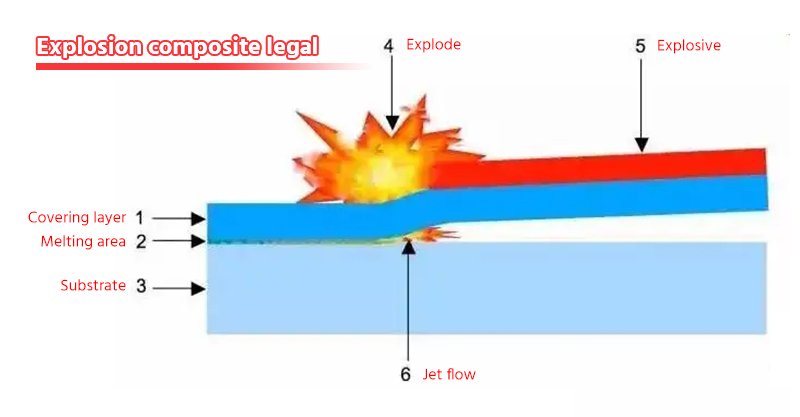

2.1 Explosive cladding method

Using explosives as an energy source, different metals are welded together in a large area under the high-speed detonation and impact of the explosives.

explosive cladding

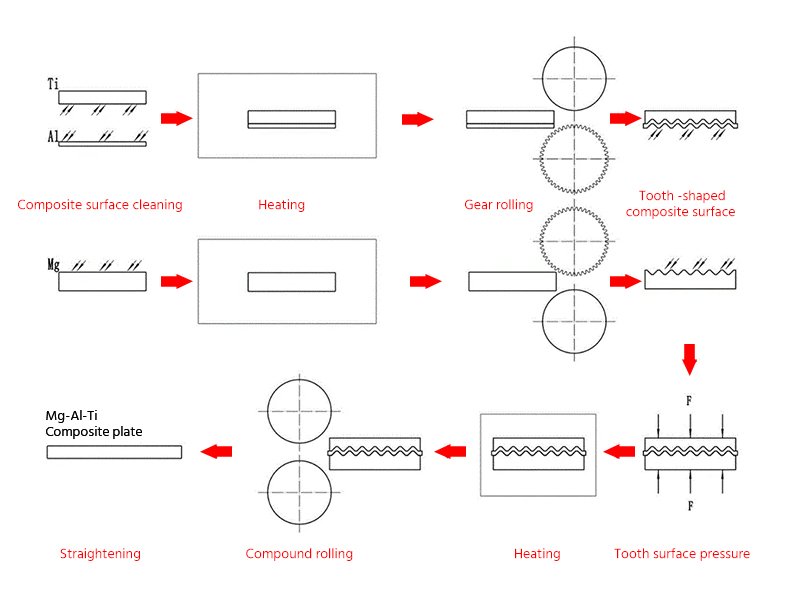

2.2 Rolling compound method

Under the action of the rolling force of the rolling mill, the surfaces of the two metals to be composited are plastically deformed, thereby causing the metal surface to crack, and the fresh metals exposed from the cracks contact each other, forming a metallurgical bond between the metals under the action of pressure. According to the temperature during rolling, the rolling composite method can be divided into hot rolling and cold rolling.

2.3 Explosion-rolling compound method

The explosion-rolling composite method refers to the use of explosive composite technology to weld two or more metal plates that need to be composited according to a certain thickness ratio to form composite slabs, and then hot-rolled according to different conditions and requirements. Or cold-rolled into a clad sheet with the required thickness specifications.

2.4 Powder metallurgy method

The powder metallurgy method is to spread the evenly mixed metal powder on the surface of the base metal for pressing, then sinter at high temperature in a protective atmosphere, and finally make a composite product by cutting.

2.5 Diffusion recombination method

The diffusion recombination method is to stick the two metals closely together and keep them under a certain temperature and pressure for a period of time, so that the atoms between the contact surfaces diffuse each other to form a metallurgical bond.

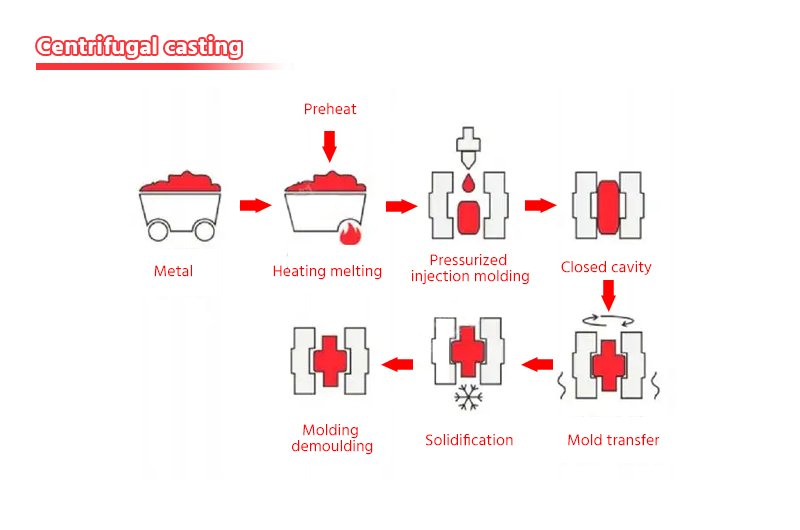

2.6 Centrifugal casting method

The casting compound method is to pre-treat the surface of the base metal and preheat it to a certain temperature, and then immerse it into a casting mold cavity filled with clad metal liquid, or put the base metal into the casting mold cavity, and then transfer it to the casting model. The cladding metal liquid is cast in the cavity, and the liquid metal solidifies and cools to form a composite material.

centrifugal casting

2.7 Continuous casting and rolling composite method

The continuous casting and rolling composite method combines the traditional casting method and rolling method. The high-temperature molten metal is continuously cast on the surface of the base steel plate, so that the liquid metal in the semi-solidified state and the solid base metal are continuously rolled on the rolling mill at the same time. The rolling force and high temperature diffusion of the liquid metal form a metallurgical bond between the two metals.

3. Application of clad metal products

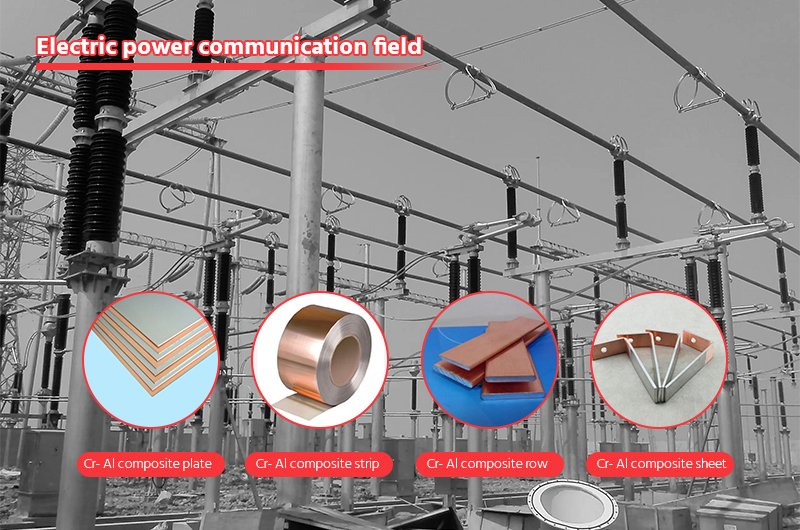

3.1 Power Communication Field

It mainly develops and produces copper-aluminum composite products such as copper-aluminum communication substrates, copper-aluminum composite transition plates, copper-aluminum composite plates and foils, lithium battery connecting sheets, copper-aluminum composite strips, copper-aluminum composite rows, copper-aluminum composite plates, etc., with a width of 600 ~1000mm, thickness 0.05~20mm, various types and specifications of plates, strips, foils, and rows, copper-aluminum communication substrates, copper-aluminum composite transition plates, copper-aluminum composite plates and foils, lithium battery connection sheets, copper-aluminum composite tapes, copper Aluminum composite row, copper-aluminum composite board

Transition Plate used in electric power and Communication

3.2 Shipbuilding Industry

Aluminum-steel, aluminum-titanium-steel marine transition joints can realize the connection of non-weldable dissimilar metals, and can greatly improve the flexibility, sailing speed and service life of ships.

Aluminum-steel, aluminum-titanium-steel structural transition joints are mainly used in high-speed ships, yachts, and near-navy ships, and can be used as structural connectors in other lightweight fields such as machinery, vehicles, and nuclear energy.

Transition Plate used in shipbuilding

3.3 Heat Exchanger Field

Carbon steel composite panels are widely used in tubular heat exchangers, boilers, pressure vessels, steam turbines, large air conditioners and other industries. Mainly used in chemical vessels, such as tubular heat exchangers, pressure vessels, boilers, condensers, air conditioners, evaporators, and seawater desalination, to support and fix tubulars. The material of titanium metal not only has high strength, but also And it has great thermal conductivity and corrosion resistance.

Transition Plate used in Heat Exchanger Field