APPLICATION

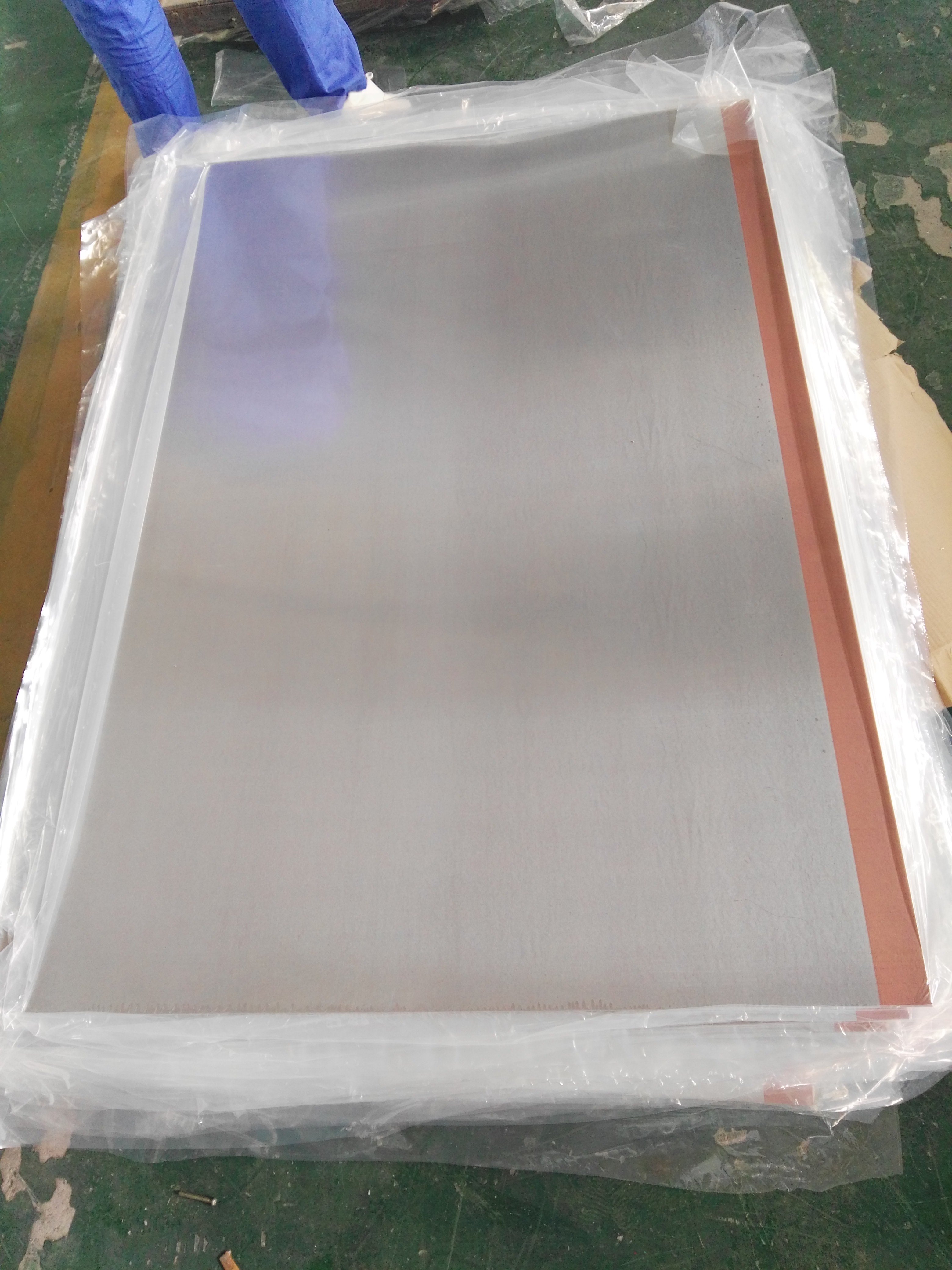

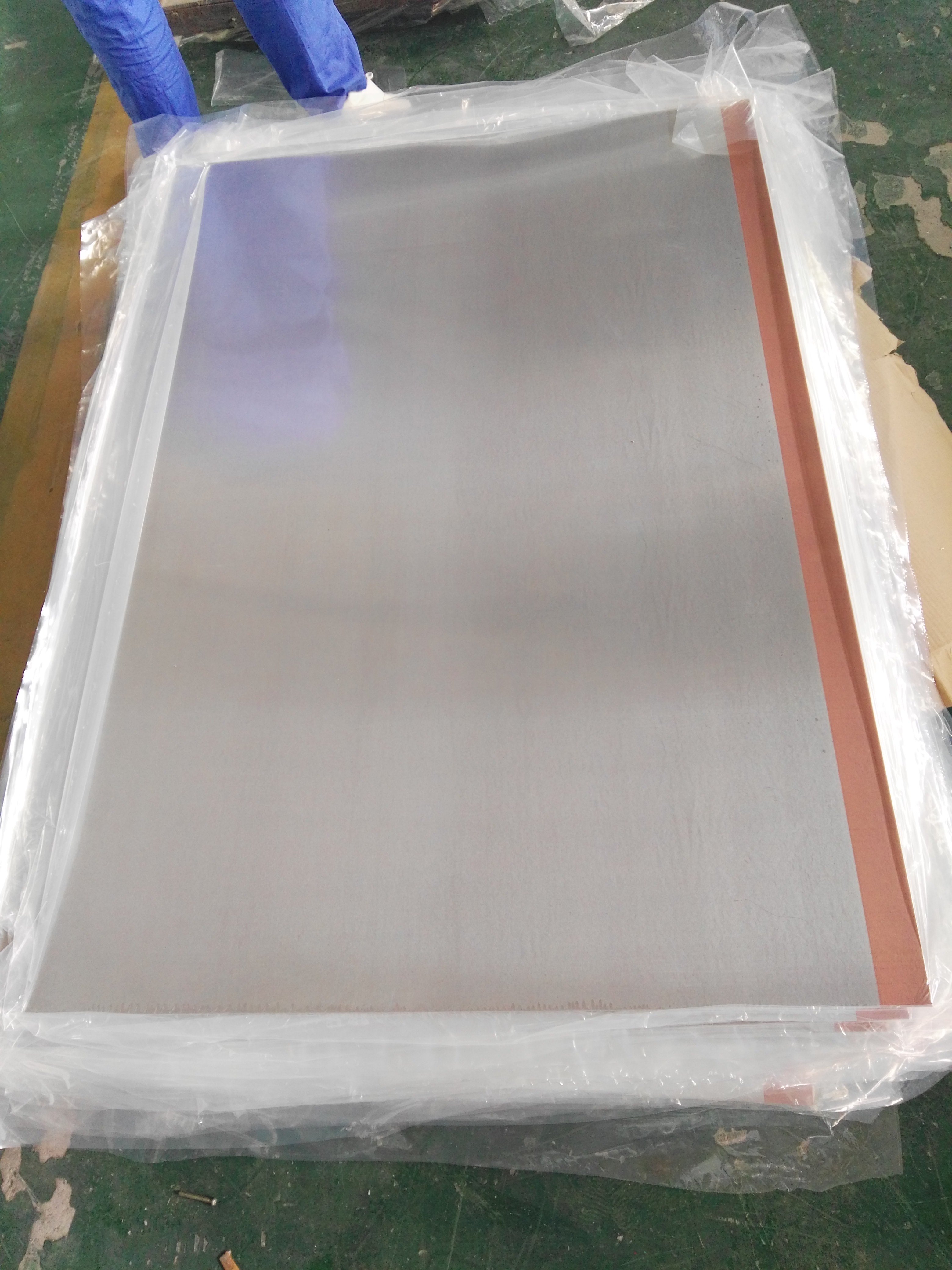

Copper-aluminum composite radiator

Editor :frank

Time :2018-09-19 11:57:00

With the development of lightweight and miniaturization in the electronics, communication and transportation industries, the heat dissipation problem of high energy density becomes more and more prominent. For example, electric vehicle inverter transformation, PL C chip heat dissipation, and high-power L ED searchlight all produce huge heat in a very small volume.However, traditional thermal conductive materials, such as copper and aluminum, are difficult to meet the demand, and the cost of silver, the best material for heat conduction and heat dissipation is too high to be applied in industrial industrialization. Therefore, a product that can give play to the thermal conductivity of copper and heat dissipation performance of aluminum is an ideal material for high energy density heat dissipation.

The copper-aluminum composite radiator developed by our company has completed the simulation of copper layer thickness, aluminum layer tooth height, tooth width and tooth space through numerical simulation calculation, and the high-power copper-aluminum composite radiator has been prepared by the semi-melting rolling composite technology of our company.Its main features are as follows

Copper - aluminum composite radiators give full play to the thermal conductivity of copper materials, heat energy derived from heat sources advantage.

It gives full play to the advantages of good heat dissipation performance and light weight of aluminum. It not only realizes the miniaturization of high energy density, but also realizes the lightweight of heat dissipation system.The metallurgical combination between copper and aluminum, and there is no contact thermal resistance between copper and aluminum, which reduces the heat transfer interface and greatly improves the heat dissipation efficiency of the system.

The copper-aluminum composite radiator developed by our company has completed the simulation of copper layer thickness, aluminum layer tooth height, tooth width and tooth space through numerical simulation calculation, and the high-power copper-aluminum composite radiator has been prepared by the semi-melting rolling composite technology of our company.Its main features are as follows

Copper - aluminum composite radiators give full play to the thermal conductivity of copper materials, heat energy derived from heat sources advantage.

It gives full play to the advantages of good heat dissipation performance and light weight of aluminum. It not only realizes the miniaturization of high energy density, but also realizes the lightweight of heat dissipation system.The metallurgical combination between copper and aluminum, and there is no contact thermal resistance between copper and aluminum, which reduces the heat transfer interface and greatly improves the heat dissipation efficiency of the system.

Related :

- Copper-Aluminium Bimetal Clad Sheet2023-04-27

- Bimetallic copper aluminum washers2020-06-30

- copper-aluminium bimetal clad sheet2020-07-08

- copper coated aluminium busbar2021-03-01

- aluminum copper clad laminate sheet2021-03-15

- is copper clad aluminum wire good?2021-03-30